- Type:RUBBER ACCELERATOR TBzTD

- Molecular:C30H28S4N2

- CAS NO:10591-85-2

- Applications:A fast curing primary secondary accelerator in NR, SBR and NBR applications.

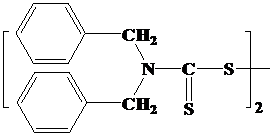

Chemical Name: Tetrabenzyl thiuram disulfide

Molecular Formula: C30H28S4N2

Molecular Structure:

Molecular Weight: 542.78

CAS NO.:10591-85-2

Specifications:

| Item | Powder | Oiled Powder |

| Appearance | Gray -white powder | |

| Assay,%≥ | 96.0 | 95.0 |

| Initial Melting Point℃≥ | 128.0 | 127.0 |

| Final Melting Point℃ | 130.0~134.0 | 130.0~134.0 |

| Loss on Drying%≤ | 0.30 | 0.30 |

| Ash%≤ | 0.30 | 0.30 |

| Residue on 63μm Sieve,%≤ | 0.50 | 0.50 |

| Residue on 150μm Sieve,%≤ | 0.10 | 0.10 |

| Oil content,% | —- | 1.0~2.0 |

| Physical property | ||

| Density at 20℃(kg/m³) | 1400 | 1400 |

| Bulk density(kg/m³) | 400-460 | 400-460 |

Properties: Gray white powder.No osmly and a little taste bitter.Souble in acetone, alcohol, insoluble in Benzene,gasoline and water.

Applications: Developed to replace thiurams such as TMTD where the presence of nitrosamines is of concern The dibenzylnitrosamine is not carcinogenic according to published literature. A fast curing primary secondary accelerator in NR, SBR and NBR applications. Be safer to progress, providing longer scorch times than TMTD.Sometime used as retarder in the vulcanisation ofPVC rubber.

Package: 25kg plastic woven bag, paper with plastic film bag, kraft paper bag.

Storage: The product should be stored in the dry and cooling place with good ventilation, avoiding exposure of the packaged product to direct sunlight. The product with pallet should not be stacked. Stacking of palletized material or temperature of above 35οC can cause unusual compacted product. Since the date of production,the storage period is 12 months.

Notes: The product could be ultrafine powder based on customer accurate requirement.